Categories Pastry Chef Articles

Types of decorative sugar and their cooking processes, by Paco Torreblanca

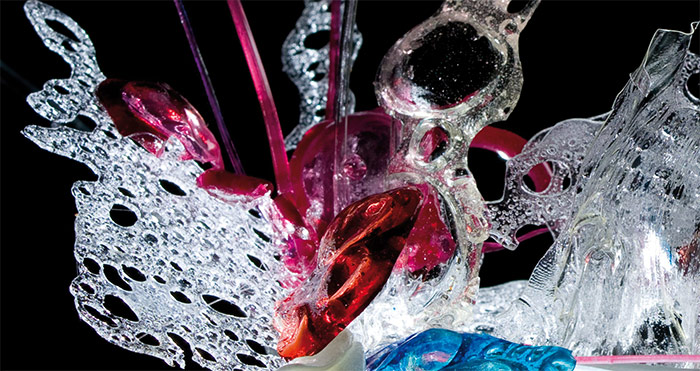

In Colección Sugarworks, Paco Torreblanca masterfully uses sugar to create a universe of shapes and colors with no limit other than the imagination. Pieces that are between architecture and sculpture, lights and shadows.

Alongside the master pastry chef, we go over of the main types of decorative sugar and their cooking, included in the second volume of this essential book.

Pulled sugar

Pulled sugar -or caramel- allows endless combinations when creating different decorative pieces. In order to obtain a good result, we have to pay all of our attention to the process, and the rules must be properly followed. Obtaining a glossy, fine caramel will absolutely depend on this.

One of the key factors to take into account when working with sugar is the cooking process. Between 350 and 400 g water are needed per 1 kg sugar. The water must as pure as possible, and absolutely chlorine- and calcium-free. Countless brands of bottled water, of an excellent quatlity for this use, are easily found in the stores.

It is essential to use fine sugar, and as white as possible. I personally prefer cane sugar, either granulated or in cubes, although fine beet sugar provides good results as well. When I create decoration pieces with satiny or pulled sugar, I like to use sugar in combination with glucose, tartaric acid, citric acid, etc.

Put the water, preferably cold, in the casserole and add the sugar. Place over a low heat, so that the sugar grains melt completely before boiling.When it comes to a boil, remove the casserole from the heat and skim the froth off the sides with the help of a damp paintbrush. Place the casserole over the heat again, but this time over a higher heat, and continue to clean the sides in order to remove the froth. Add the glucose (around 200 g) and, when the temperature reaches 155°C, add approximately 12 tartaric acid drops. Allow to cook to 160°C.

If we consider using cream of tartar in our recipe, it is advisable to add it together with the sugar, previously dissolved in some water.

As for the coloring process of sugar, coloring powder should be used, diluted in white alcohol in a ratio of 4 equal parts of water to 1 equal part of alcohol and coloring.

For example, for 400 g water, we should add 100 g alcohol mixed with 100 g coloring powder.

In order to obtain very light colors, the caramel can optionally be colored after being cooked, before satinizing. If we want to obtain deeper and more solid colors, we have to color during the cooking process. It is advisable to add the coloring at a temperature between 130°C and 135°C.

Remove from the heat and cool the casserole with very cold water in order to let the cooking come to an end. Let sit for a few minutes and pour over a Teflon surface.

Work the caramel by turning the sides over into the center, gathering it into a ball and making sure that all the mass cools down evenly. Try to avoid a too high addition of air into the mass. When working, always avoid the draft and places with a high humidity factor.

When the caramel is firm enough as to form a braid, pull it and fold it over between 20 and 30 times in order to provide it with gloss. The best temperature for the sugar to acquire a proper glossy aspect is between 75 and 80°C. It is important not to pull the sugar at a too high temperature, as this would add a too high amount of air into it and it would consequently take a longer time to dry, thus losing its elasticity and shine. It is also essential not to work it at a too low temperature either, as it would be much harder for us to handle and this would result to a more transparent and less glossy caramel.

If the aim is not to work on decoratations or any other task at that very moment, it is advisable to keep the mass between two Teflon mats, allow it to cool down and store it in plastic bags inside boxes with some silica gel or calcium chloride until further use. When needed for use, it can be heated in a microwave oven, or the caramel sheets can be alternatively placed below a heat lamp until reaching a temperature of 75 or 80°C again for satining.

Casting sugar

The casting sugar technique allows us to create figures, disks, bars, bases… countless shapes with which artistic pieces can be created to be used in display cabinets, competitions, commemorative events, etc. These sugar structures can also be combined with other pieces made with pastillage, bubble sugar, isomalt and other types.

The recipe

- 1000 g sugar

- 400 g cold water

- 250 – 300 g glucose

To prepare casting sugar or caramel, proceed as follows.

Put the sugar and the cold water into a copper casserole or an electric saucepan and then over the heat. Always make sure the containers have been cleaned properly. Start to cook over a low heat, and when it comes to a boil, remove from the heat. Clean then the sides of the casserole with the help of a paintbrush and skim the froth off the surface. Add the glucose and place over a high heat. Clean the sides again with the paintbrush and remove any forming froth. Cook to 160°C. Rapidly cool down by submerging the casserole in a container with cold water and allow a few minutes for the bubbles to disappear. If coloring the sugar is desired, add the colors at a temperature between 135 and 140°C.

Marble-like casting sugar

To prepare this kind of sugar, the same recipe as that of castig sugar above should be followed. When it reaches a temperature of 135°C, the titanium dioxide should be added, which will make the sugar become opaque. The whiteness of the sugar will depend on the amount of dioxide added.

If an imitation of marble is desired, when finishing the cooking at 160°C, remove from the heat and add the coloring. It is essential not to mix the coloring into the sugar, but just draw one circle with the spatula. Immediatly pour over the molds. This is how an imitation of marble can be obtained.

Bubbled sugar

This type of sugar is perfect for commercial artistic presentations, such us decoration of ice creams, desserts, etc. It also provides the pieces with extra volume and highlights the whole work. Both the recipe and the cooking process are the same as for casting sugar. It is necessary to emphasize again that in order to achieve good results, it is essential to keep the casseroles or the saucepans used always clean, by constantly brushing down their sides to prevent any crystallization of sugar.

Unlike for casting sugar, do not cool down with cold water. Instead, pour a small amount of sugar over some parchment paper (not all the types of parchment paper give the same result though). Add some coloring drops if desired and wave the paper to and fro in order to allow the bubbles to form.

Using this technique, I have created a type of bubbles with a more transparent and thicker structure which provide decorations and artistic pieces with more volume and brightness.To make them, pour a small amount of sugar over the center of the paper and place another piece of paper on top, covering the sugar. With the help of a rolling pin, roll out to a thickness as regular and thin as possible all along the paper. Allow to cool down completely, remove the paper which had been placed on top, transfer the sugar to a holed tin (like the ones used for baking) and bake in the oven at 120-130°C. The heat will go through the holes and will form transparent bubbles, which will look like soap bubbles. When cold, this sugar will be ready to be used for decorations.

Other types of decorative sugar that you can find in this book are…

Also discover the first volume of Colección Sugarworks, which proposes an exciting tour of some artistic sugar and chocolate pieces, cakes, and desserts, like White snail, Wood or Nile, water of life, with author’s comments.